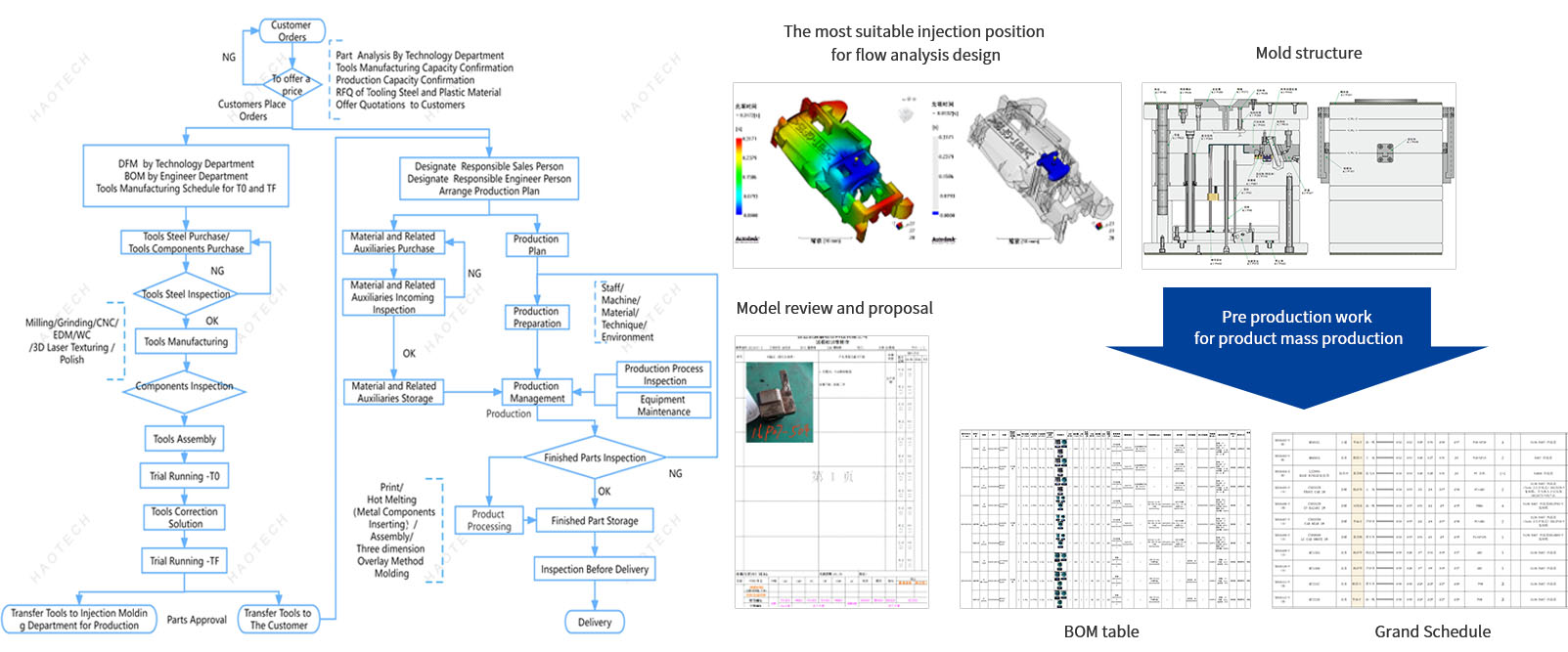

Before mold processing, business, technology, engineering and customers will communicate, coordinate and review many times.

Discuss matters related to products, including parting line, mold entry point determination (mold flow analysis), steel selection, mold structure (sub, diagonal pin, sliding block and other institutions), poor gas trapping and exhaust, etc.

Our company has professional mold knowledge and practical experience, and will rely on professional knowledge to reduce possible problems in the early stage.

After many times of rubbing, the processing can be officially started to reduce the problems after subsequent processing and die testing

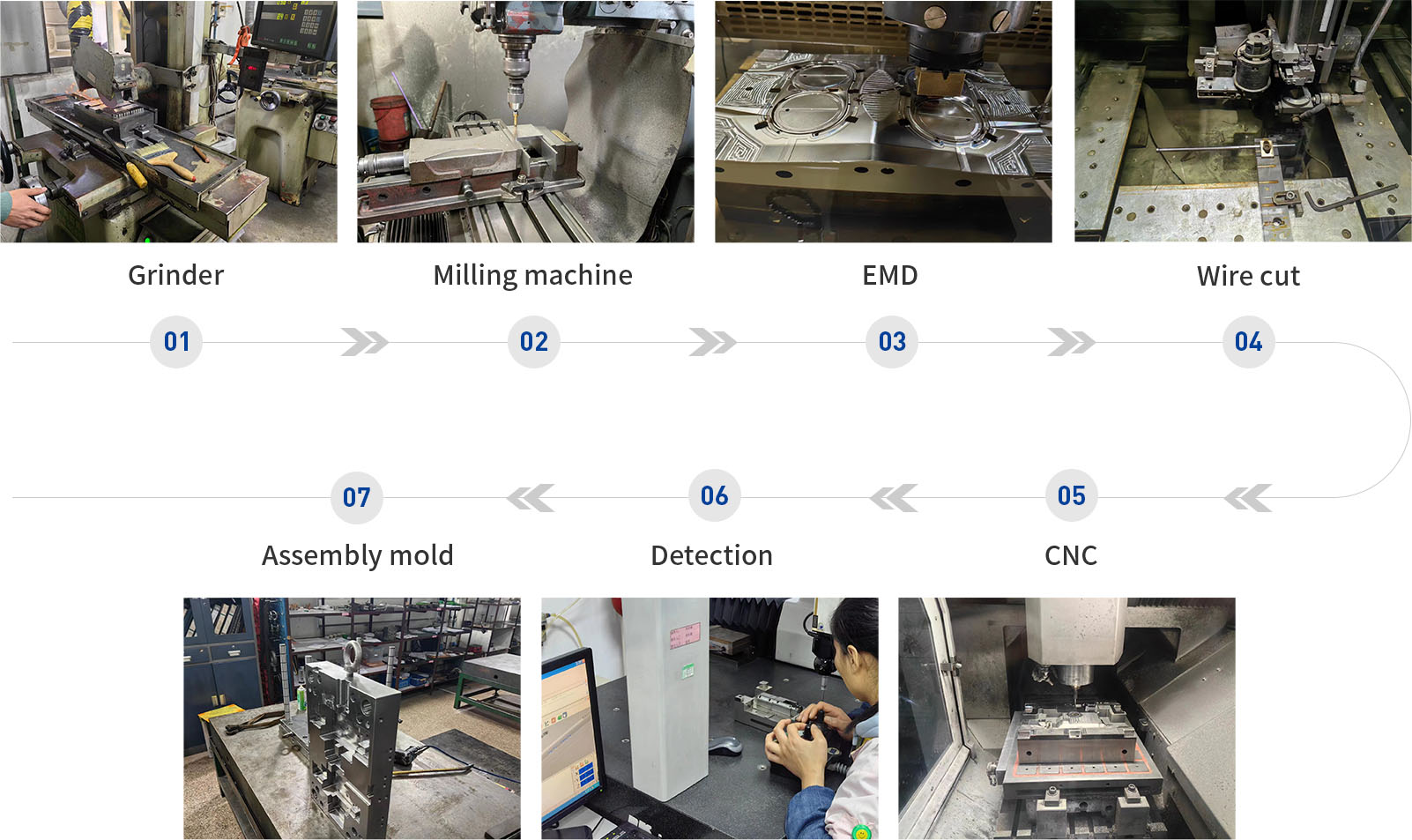

According to different mold structure requirements, each step of the mold processing process requires strict requirements and operations to ensure perfect mold quality.

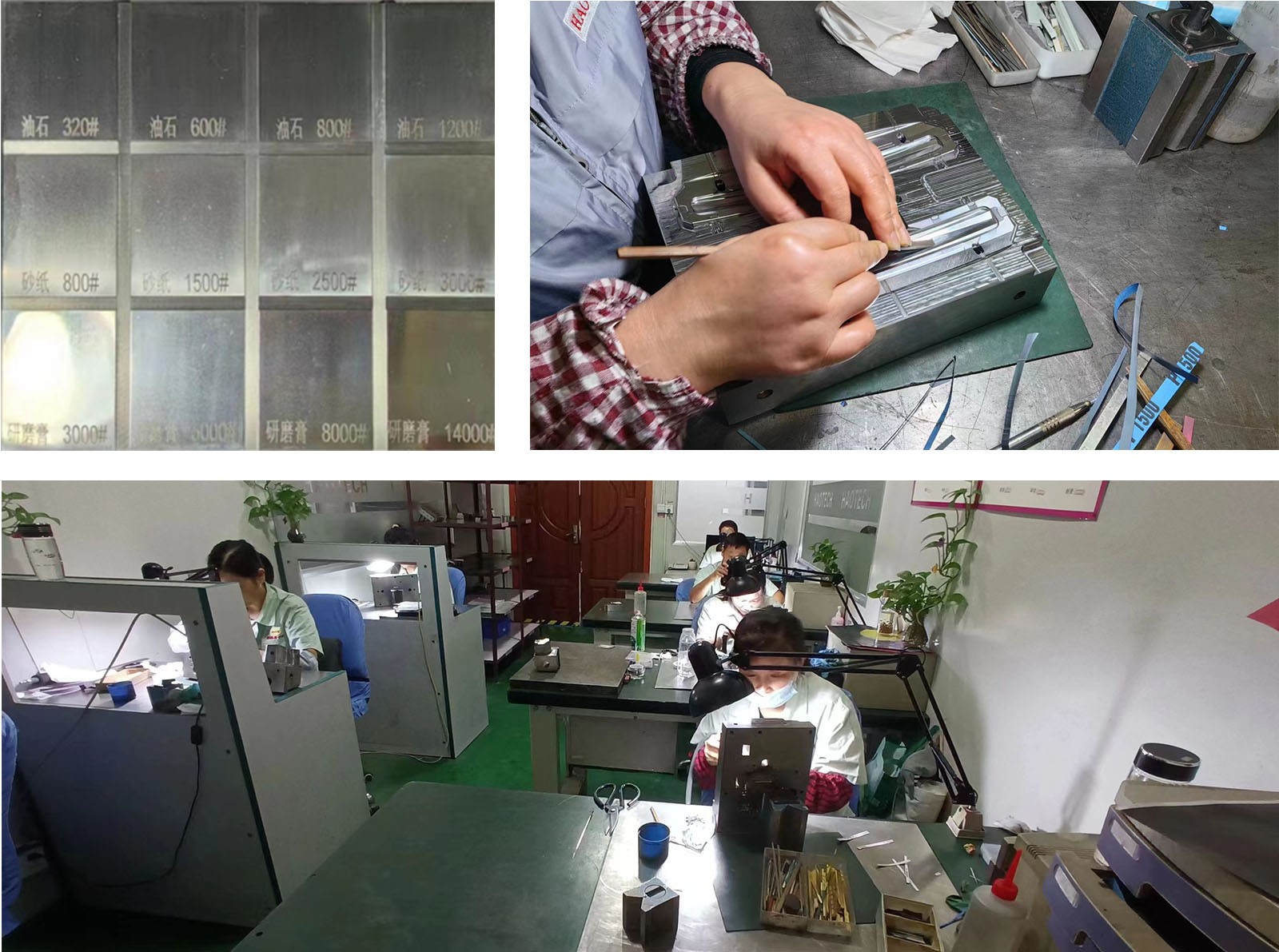

To achieve high-quality polishing results, it is necessary to have tools and polishing supplies such as oilstones, sandpaper, diamond grinding paste, grinding oil, etc. After polishing, the surface of the product will have a significant mirror effect. Polishing grade: 320 #~14000#